THE NEW BEYERDYNAMIC DRIVER IN OUR PRO X HEADPHONES

You have sent us a lot of questions about our new STELLAR.45 driver. In this blog article, we provide answers to your questions and team up with our engineers to give you detailed insights into how this new technology was developed and how it works. We are delighted by your keen interest in the technical details and hope you enjoy reading about them.

TABLE OF CONTENTS

In which headphones is the STELLAR.45 driver installed?

We have developed the STELLAR.45 for our new PRO X series and it is consequently employed in the new DT 700 PRO X and DT 900 PRO X headphones.

What makes the STELLAR.45 driver so special?

When developing the driver system for the PRO X headphones, we focused on making the transducer highly efficient as well as capable of delivering a superb sound performance. By efficiency, we mean the ability to convert electrical signals into sound with as little loss as possible. A high level of efficiency means that the speakers in the headphones are able to perform well with mobile devices as well as on stationary systems such as digital audio workstation or headphone amplifiers. Thanks to various technical techniques, we were able to develop a driver that is superior to our Classic drivers in terms of efficiency. On top of this, we also put a lot of work into enhancing the design of the transducer’s voice coil. The result is a relatively long coil, but one that remains extremely lightweight. In combination with an innovative diaphragm structure, we were able to create a speaker that reproduces the acoustic signal with a minimum of distortion even at higher volumes.

Which components form part of the STELLAR.45?

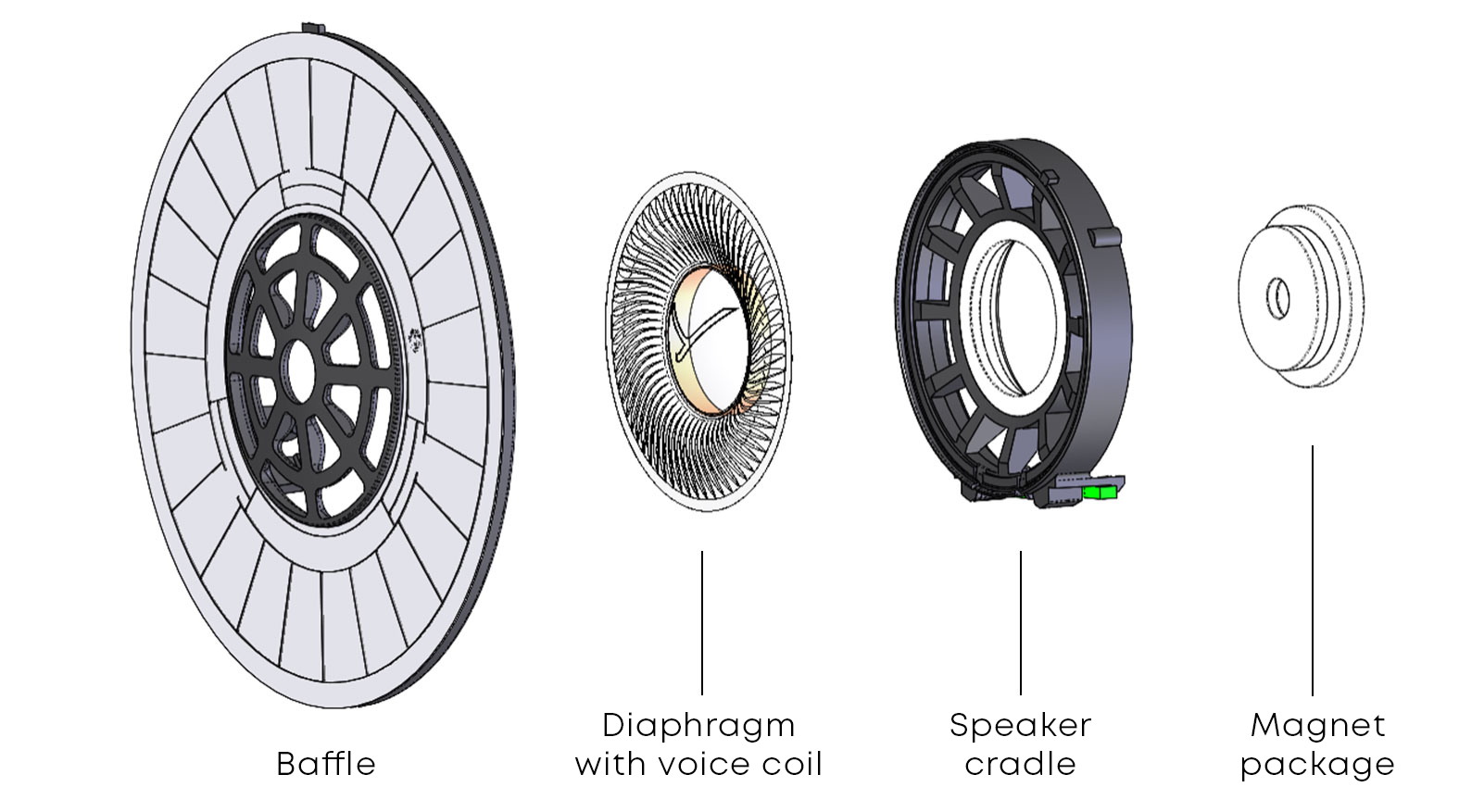

The STELLAR.45 driver is made up of four main components: diaphragm with voice coil, speaker bearing, magnet unit and baffle.

At the heart of the STELLAR.45 is the diaphragm and coil. This system is driven by an electrodynamic force caused by an electric excitation signal. The 3-layer structure of the diaphragm ensures consistent and controlled oscillation even at high sound pressure levels. All components come together in the speaker’s bearing, in which a precision-manufactured metal ring is integrated during the manufacturing process. Metal ring and magnet form a 0.6 mm wide magnetic gap. The voice coil must be precisely positioned in the centre of this gap to enable uniform oscillation of the membrane.

The high efficiency of the STELLAR.45 transducer is also achieved through use of a top-class N52 neodymium‑iron‑boron (NdFeB) magnet. Thanks to the tiny magnetic gap size and high quality of the magnet, a field strength greater than one Tesla is created within the gap. The speaker is positioned within the headphones using the baffle, and acoustically fine-tuned by means of its fleece covering.

For further details about individual components watch our behind-the-scenes-video.

How is the STELLAR.45 driver different from the previous beyerdynamic drivers?

The roots of the STELLAR.45 clearly lie in the tried-and-tested Classic drivers used in top models such as the DT 770 PRO, the DT 990 PRO and the DT 880 PRO, but also in the MMX 300 and other headsets in the DT 79X series.

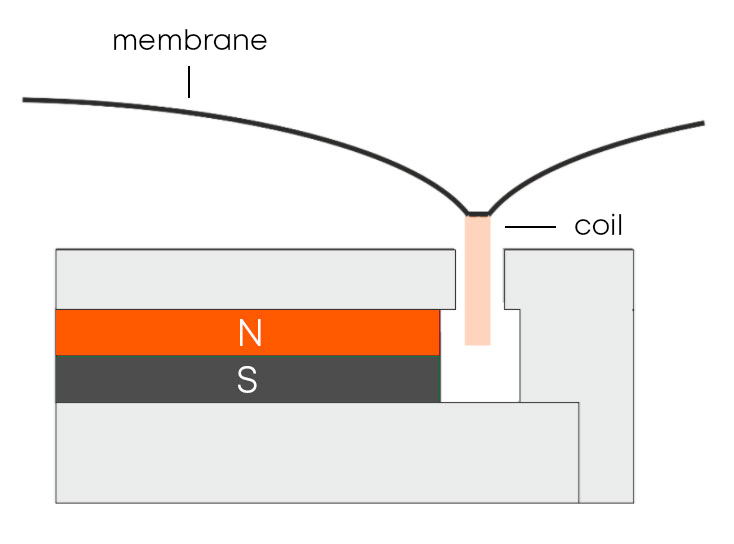

In its basic structure, the STELLAR.45’s magnet pot is similar to that of the Classic driver, but the magnet pot and voice coil have been given an enhanced design. In combination with the powerful NdFeB magnet, the STELLAR.45 driver is able to convert electrical signals to sound with a similar degree of efficiency to that of our Tesla transducers. This means that the transducer is able to produce almost identical volumes given the same input. In the case of both the Classic drivers and the STELLAR.45, the magnet is positioned in the centre of the pan, i.e. within the voice coil (fig.1).

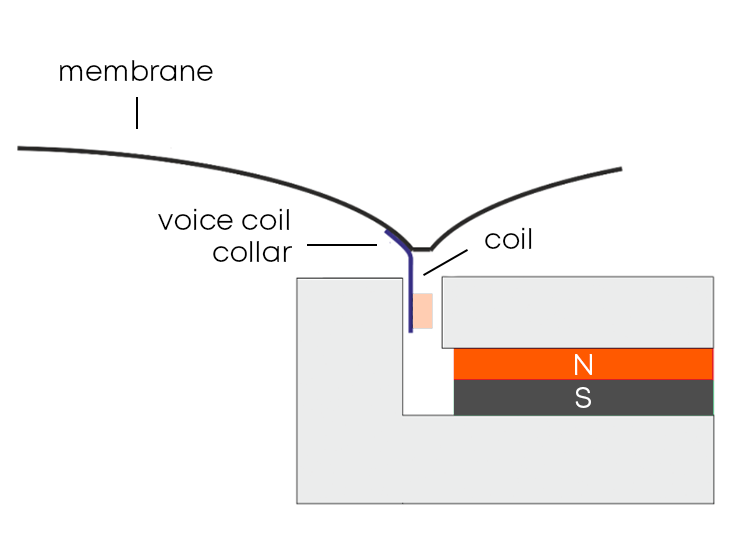

Fig. 1: Cross-section diagram of coil arrangement

For a headphone driver, the STELLAR.45’s voice coil is remarkably long, and is the first to be given a symmetrical overhang. This means that the voice coil runs through the complete magnetic gap and protrudes to the same degree above and below it. Consequently, the coil can take advantage of the full range of magnetic flux in the gap. The driving force remains constant even with longer diaphragm strokes so that distortions are reduced to an absolute minimum.

An extremely thin copper-clad aluminium wire is used for the voice coil. With a diameter of just 60 µm, this wire is as thin as a human hair. To improve its durability, the wire is also given a special coating. The density of the composite material is only half that of pure copper, but still boasts excellent electric conductivity. Weighing around 80 mg, the weight of the 3.2 mm long voice coil is considerably less than that of the coils used by other driver manufacturers.

We also use powerful NdFeB magnets in our Tesla drivers, but these are arranged in a ring shape outside the voice coil. Due to the larger surface area of these ring magnets, with Tesla drivers a higher magnetic flux is coupled into the magnetic circuit, and this is a factor affecting the characteristics of the magnetic field in the gap. The optimum characteristics for the transducer depend on the type of voice coil used. In contrast to the STELLAR.45 driver, the Tesla driver has an underhung voice coil (fig.1). This voice coil is located on a collar that positions it in the middle of the magnetic gap. With a height of 0.7 mm, the height of this underhung voice coil is significantly less than that of an overhung voice coil, such as that in the STELLAR.45. Owing to this, the delicate voice coil in the Tesla driver weighs just 20 mg. It is generally true that this underhung arrangement permits ultra-light coils with low winding height and low weight.

What is interesting, however, is that our voice coils are consistently significantly lighter than those of other driver manufacturers –and this has an impact on the sound. Because the mass of the voice coil is less, the diaphragm is able to follow the excitation signal more quickly, and this makes for excellent reproduction of transients.

Discover our new TESLA.45 sound transducer, which is built into our new studio headphones DT 1770 PRO MKII and DT 1990 PRO MKII.

In the blog post Sound revolution with the new beyerdynamic driver – the TESLA.45, our acoustic engineer Ante provides exciting information about the development of the Tesla technology and beyond.

What were the challenges we had to overcome during development of the STELLAR.45 driver?

The biggest challenge we faced during development of the STELLAR.45 was to continue the legacy of our tried-and-tested DT Classic transducer and optimise it wherever possible.

We focused on creating a transducer with a high degree of efficiency and capable of producing the highest possible sound pressure level. The design therefore called for the transducer to cause the lowest possible distortion of its own even at very high sound pressure levels. Distortion of this kind would falsify the original audio signal and needed to be kept to an absolute minimum. Despite all this, we wanted of course to retain the brilliant high-frequency reproduction for which beyerdynamic headphones and transducers are renowned. A further challenge was to develop a driver suitable for open-backed as well as closed-back headphones. The transducer’s sound pressure had to be free of troughs and narrowband spikes across the entire audible range. This would enable the driver to be an all-rounder and provide optimum conditions for the headphone’s acoustic design.

On top of all this, our engineers were committed to ensuring an exceptional level of quality and consistency in transducer production. Because of the high level of automation on the production line, special attention needed to be paid to the reliability of the assembly processes. In this context, we would like to make special mention of the process for mounting the diaphragm and voice coil in the speaker bearing. As we have already mentioned, the gap between magnet and metal ring is just 0.6 mm, and the voice coil needs to be inserted and secured precisely in the middle of this gap. To ensure the required level of precision, we developed a fully-automated assembly process specially for the STELLAR.45, with a totally coordinated series of steps.

The selection of high-quality materials also played an important role in ensuring a consistently superb sound from every driver we produce. A high-performance polymer, PEEK (polyether ether ketone) has proved to be the ideal material for the surface layers of the diaphragm. It is form-stable and boasts high resistance to environmental influences such as temperature and moisture. What’s more, all plastic components were manufactured using high-quality polyamide (PA6) reinforced with glass fibre, ensuring great robustness to external mechanical influences.

Why does the STELLAR.45 driver have 48 ohms?

The goal of our engineers was to develop a long voice coil that still remained light in weight. We also wanted to create a speaker capable of delivering a stunning performance on mobile devices, and we ensured this by means of a high voltage sensitivity. Consequently, the coil needed to have a low electrical resistance. The result is as much power as possible at low signal voltages, and therefore a high driving force (Lorenz force) for the coil.

The coil’s impedance of 48 ohms consequently results from the above-mentioned goals and the wire we chose to use. On top of this, the figure of 48 also reminds us of beyerdynamic’s legendary DT 48 headphones.

That’s all what we wanted to write about on this topic. The following video will give you additional insights into our production, design and product management activities.

Wie bewertest du diesen Artikel?

Rating: 5 / 5. Anzahl Bewertungen: 2